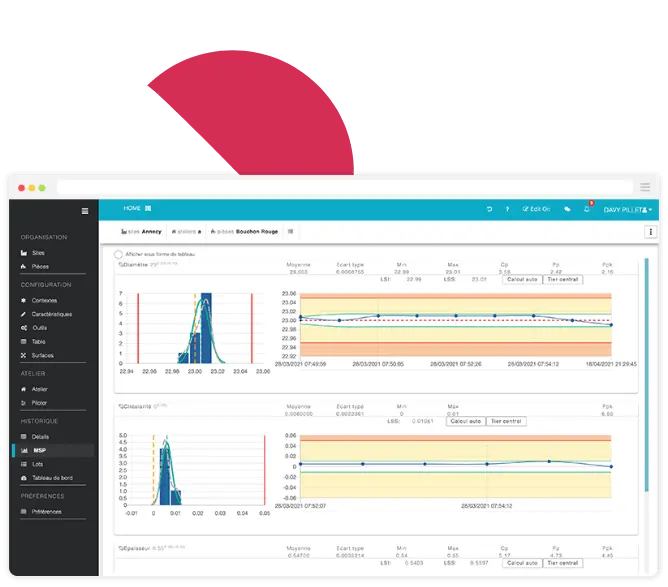

Master your processes

Monitor your processes using statistical standards: control chart, capability, etc.

Master your processes

Our SPC (Statistical Process Control) module is designed to monitor your manufacturing processes in real time.

1 interview

4 hours of training

1 month test

Your gains

-33%

Reduction of

reject rate

-50%

Reduction of

control time

4h

Training

only

How does it work?

Your benefits

Easy to install and use

Secure

Ultra simple

Adaptable

User guide

1 month test

Your feedback

During the first quarter of 2021, we deployed the Ellistat SPC tool on all our production lines (8 stations) and in the quality control laboratory (4 stations). We already had long experience of using SPC software. The Ellistat application is more user-friendly and easier to use than our old tool, especially for the parameterisation part (creation of sites, workshops, machines and parts (we have a lot of references to manage and the duplication was a great help)). The Ellistat team helped us in this implementation phase thanks to their accessibility, competence and responsiveness (as well as their friendliness). Even though Davy sometimes 'pulled his hair out', developments and improvements to meet our own needs were quickly implemented and others are planned with the Ellistat team.

Equipping our workshops with Automated Process Control via Ellistat has radically changed the way we set up and control our machines. We have been able to develop a new culture of variability control that is more dynamic and efficient, with tangible results in terms of quality and productivity. Production staff are working much more comfortably, and we can easily envisage greater complexity - the possibilities are enormous!

Ellistat is a production tool that perfectly meets the expectations of Industry 4.0. Automated Process Control makes it easy to control the numerical controls, while guaranteeing a very high level of quality.